Technical information

Airtech nitrogen generators – cost-effective and independent

The use of AIRTECH nitrogen generator requires no structural changes. The generator comes with the compact and foundation-free modular design made with very little floor space, and a change of location is possible at any time.

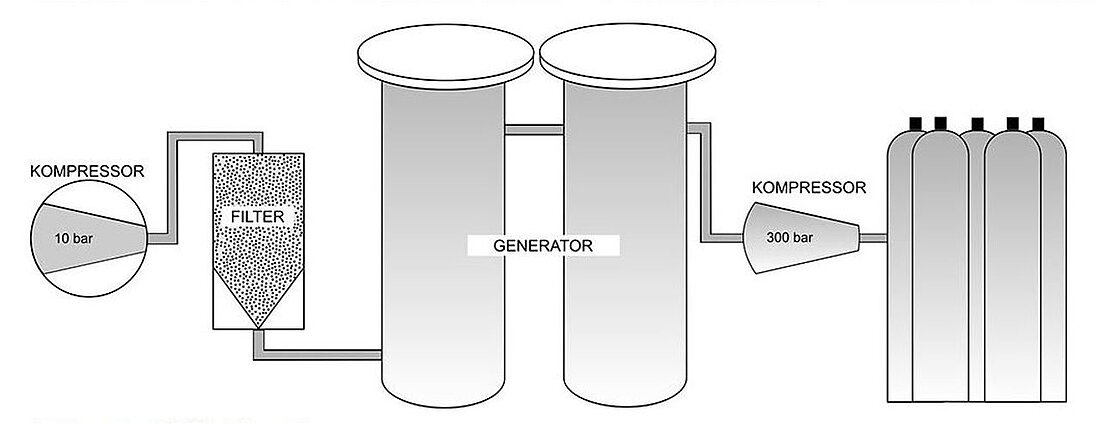

Pressure swing adsorption processes (PSA)

With the fully automatic AIRTECH nitrogen generator nitrogen is obtained in adjustable purity of normal ambient air. The generator is supplied with purified and dried compressed air, which is then broken down through a molecular sieve into oxygen and nitrogen. For greater work pressure and fluctuating quantities of nitrogen obtained can additionally compacted and in Buffer tanks are cached.

Functionality PSA nitrogen generator

Two filled with carbon molecular sieve containers are mutually pressurized air, the oxygen and other gases are filtered out. The containers are mutually filled with high-purity, dry and oil-free compressed air, and saturation of a container is switched to the next. This method is referred to as pressure swing adsorption. The change of the container is fully automatic, with the changeover is controlled by sensors as a function of saturation.

General

Our nitrogen generators produce high purity nitrogen to 99.9999% N2. The units can be easily adjusted via a touchscreen panel, with the system regulates itself. Our generators are designed to be an annual plant maintenance sufficient to ensure a continuous and reliable supply of nitrogen.

Practice

The production of nitrogen for the industry and the manufacturing sector can be realized maintenance and cost by using our generators today. Both the decentralized structure as well as easy integration into existing gas systems provide a flexible and reliable nitrogen generation at the consumption.

Your benefits

- adjustable, monitored high quality of nitrogen

- permanent availability

- low installation and operating costs

- almost infinite life of the asset

- Environment and resources are conserved

- Account for security risks in dealing with bottles

- compared to nitrogen gas cylinders possible cost savings up to 80% – no costs for rent and transport

- Waste heat effectively continue to be used as for hall heating or for hot water heating